BioLoop Surfactants

- Sean Hodgkinson

- Sep 14, 2021

- 2 min read

Updated: Jun 21, 2023

The next generation of green surfactants

Introducing a new range of bio-based surfactants containing components that

are from renewable sources. Unlike many biobased surfactants, these products

offer excellent surfactant properties and can be used as green alternatives to

conventional synthetic nonionics, such as alcohol ethoxylates. The BioLoop has two

soybean hydrophobic sections that are linked by a hydrophilic loop of polyethylene

glycol derived from molasses. Unlike palm-based surfactants, the BioLoops contain

soybean oil which is considered to be a great sustainable source.

Key Features

• Based on BioLoop technology

• Biobased

• Ultra-Mild

• No skin or eye irritancy

• Low ecotoxicity

• Biodegradable

• Good detergency

• A green alternative to alcohol ethoxylates

PG (Pure Grade) v Normal Grade

The normal grade of BioLoop surfactants are aimed at standard industrial-based

processes in which clarity in an aqueous medium isn’t a necessity. The PG versions

which denotes our purified grades are for industries in which clarity in aqueous

mediums is essential.

Typical Applications

Normal Grades PG Versions

Oils and Lubricants Personal Care

Emulsion Polymers Cosmetics

Agrochemical additives Household products

Textiles auxiliaries

Hand and floor wipes

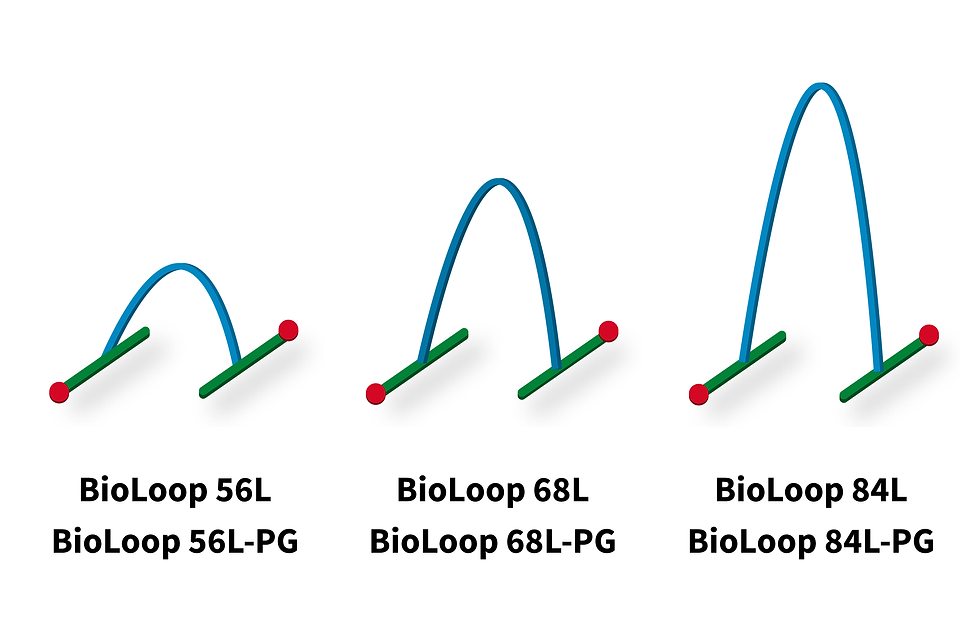

Product Range

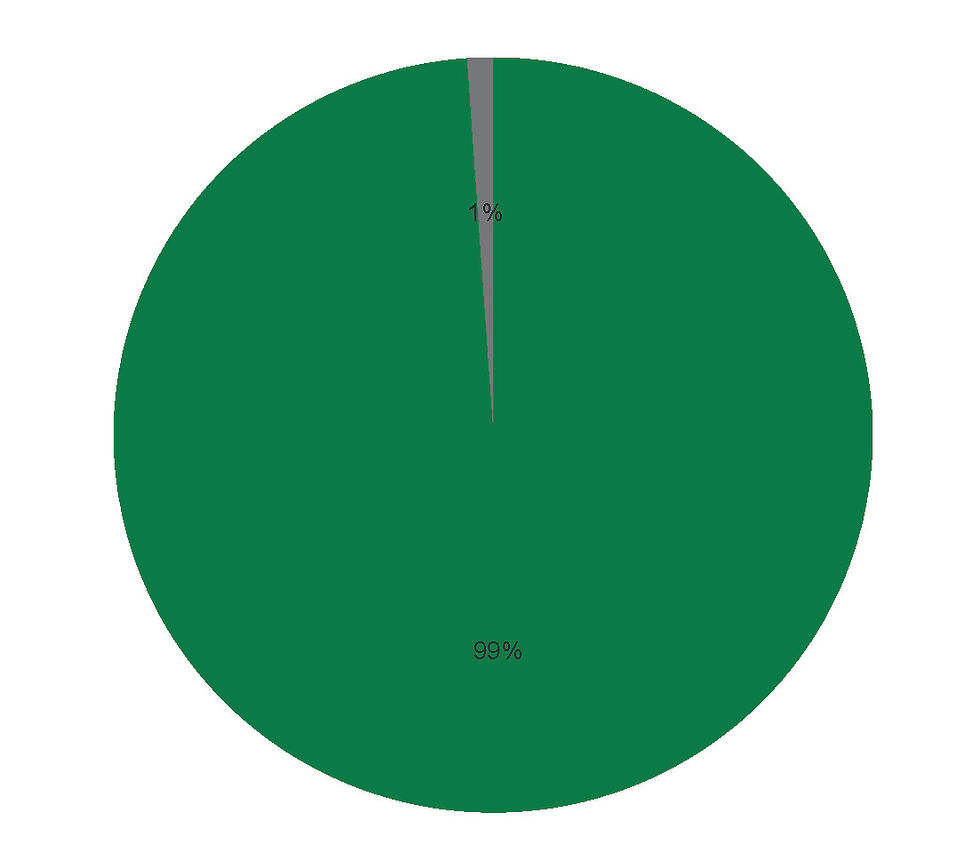

Radiocarbon (C14) dating

Result: 99.36% Biobased carbon

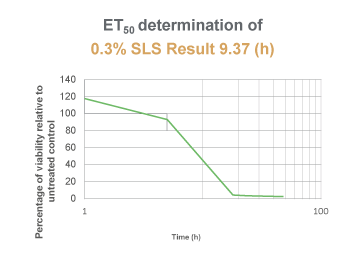

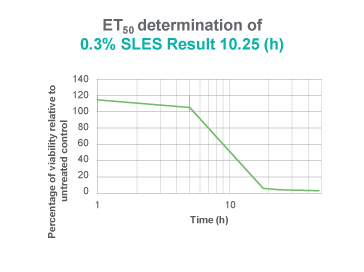

Mildness Studies

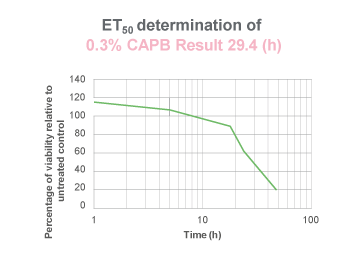

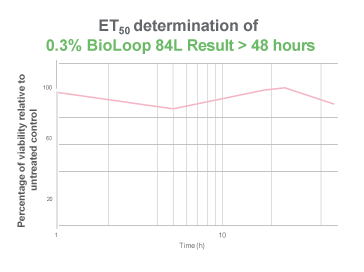

The ET 50 test method

The in vitro test was successfully adapted from the widely used ET50 method using human reconstructed skin models. Formulations are applied to the skin model surface for defined time points, followed by determination of any damage to the skin cells, using an indicator of intracellular metabolism. Test results are expressed as the ET50 value - the time taken for viability to drop to 50% of the untreated control.

The results indicate that the BioLoops, in this instance BioLoop 84L, gave a result to show extreme mildness.

Degree of mildness

Foaming Profile

Test method

A 0.1% solution is prepared and aerated for 30 seconds and then stopped. The degree of foaming is assessed after 60 seconds: A foaming classification was then defined using comparative foaming date generated across the whole of our product range.

BioLoop 56L type: BioLoop 68L type: BioLoop 84L type:

Classed as Classed as Classed as

extreme low foam medium foam medium foam

Product Links

Product Pages

Sample Requests

Opmerkingen